Does it ring a bell 🔔 ?

Here is a collection of things that improve printing with clipper when using Cura 5.5. This is the 2nd installment of a series of articles documenting my journey in “upgrading” an old (2019) Creality Ender 5 with Klipper.

The current problem while printing is, that I get a lot of ringing. Let’s find out what causes it.

The printer has a few hardware modifications installed:

- BL-Touch

- TL Smoother (Diode filter for motor drivers)

- Bed Support (to stiffen the Bed)

- Polypropylene Build Plate

- Metal Extruder Kit

Printer Setup

These are the settings currently being used for printing. This is mostly stock Cura settings for Ender 5.

Ender 5 Startup G-Code

M220 S100 ;Reset Feedrate

M221 S100 ;Reset Flowrate

; make sure bed is at 60 degrees, then level

SET_HEATER_TEMPERATURE HEATER=extruder TARGET={material_print_temperature_layer_0}

SET_HEATER_TEMPERATURE HEATER=heater_bed TARGET={material_bed_temperature_layer_0}

G28 ;Home

; calibrate bed

M190 S{material_bed_temperature_layer_0}

BED_MESH_CALIBRATE

; clean extruder

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

G1 X10.1 Y20 Z0.28 F5000.0 ;Move to start position

G1 X10.1 Y200.0 Z0.28 F1500.0 E15 ;Draw the first line

G1 X10.4 Y200.0 Z0.28 F5000.0 ;Move to side a little

G1 X10.4 Y20 Z0.28 F1500.0 E30 ;Draw the second line

G92 E0 ;Reset Extruder

G1 Z2.0 F3000 ;Move Z Axis up

; start printing

START_PRINT BED_TEMP={material_bed_temperature_layer_0} EXTRUDER_TEMP={material_print_temperature_layer_0}

Some basic settings for the printer: ender5_klipper_petg.curaprofile.

Base settings (PETG)

1[general]

2version = 4

3name = Standard Quality Ender5 Klipper

4definition = creality_base

5

6[metadata]

7type = quality_changes

8quality_type = standard

9intent_category = default

10position = 0

11setting_version = 22

12

13[values]

14cool_fan_speed = 100

15material_print_temperature = 235.0

16speed_print = 250

Ender 5 Settings (PETG)

1[general]

2version = 4

3name = Standard Quality Ender5 Klipper

4definition = creality_base

5

6[metadata]

7type = quality_changes

8quality_type = standard

9setting_version = 22

10

11[values]

12klipper_accel_limit = 8000

13klipper_accel_to_decel_limit = 1500

14klipper_corner_velocity_limit = 5

15klipper_velocity_limit = 300

16klipper_velocity_limits_enable = True

17material_bed_temperature = 100

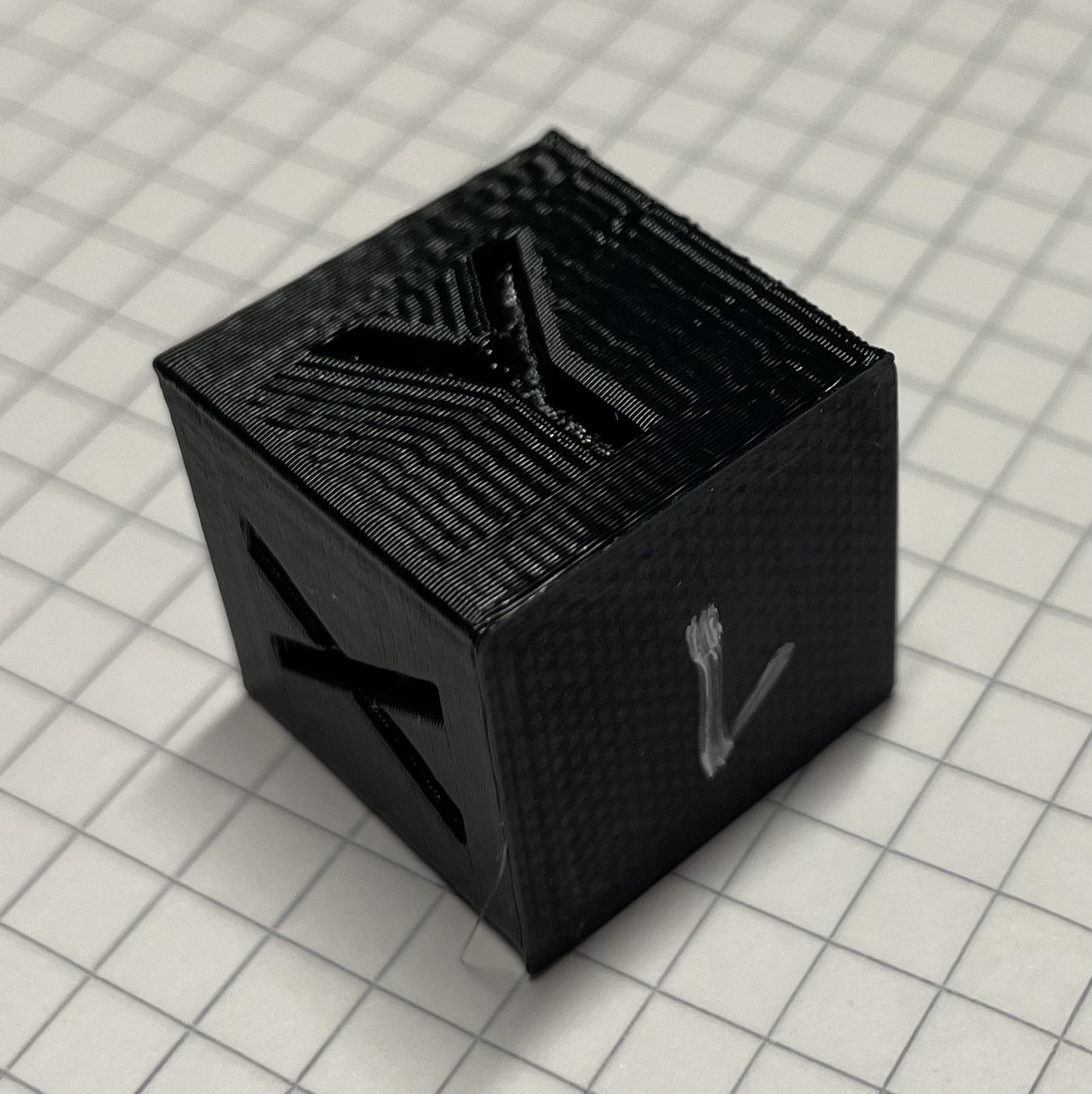

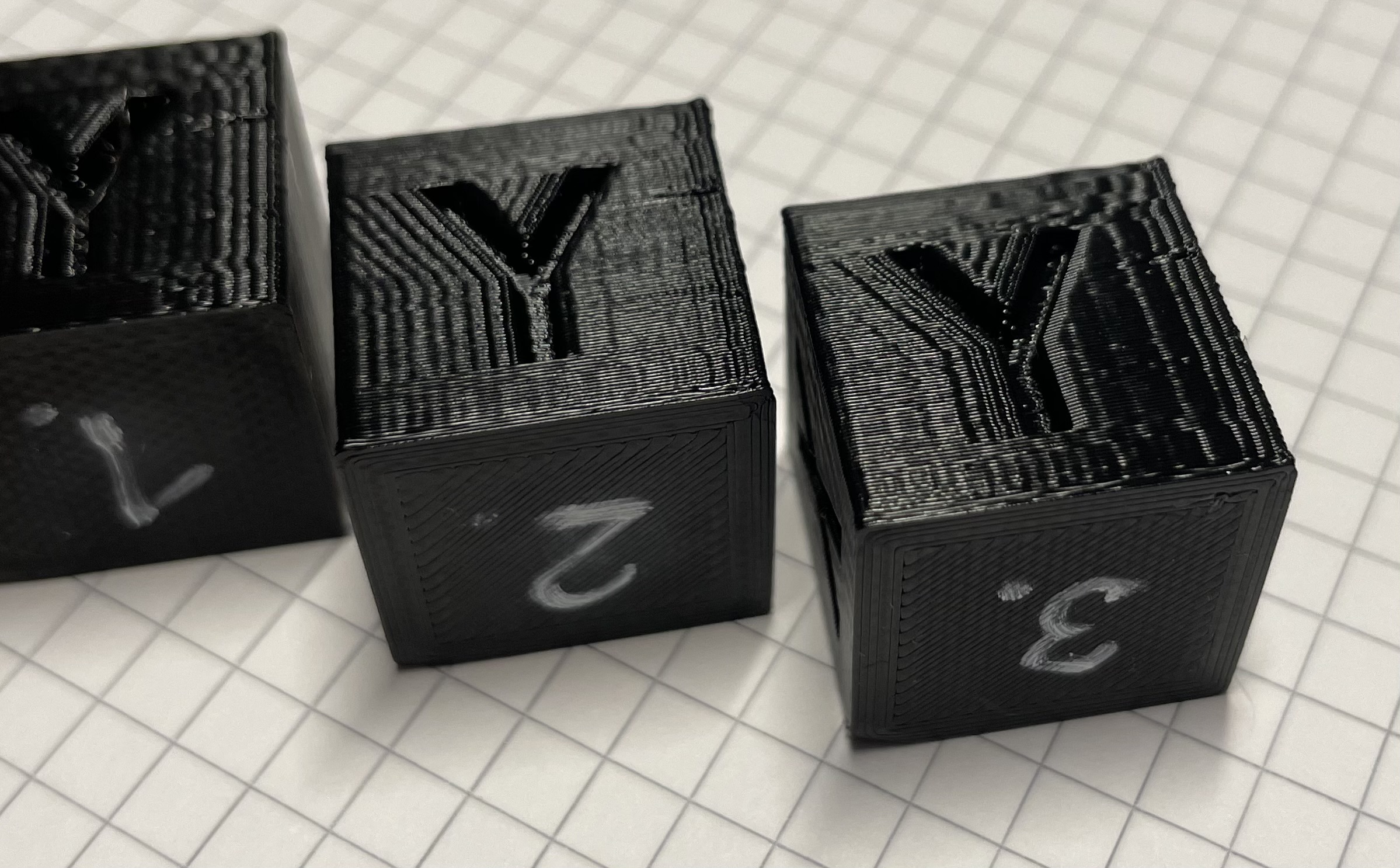

Base line prints with PETG XYZ Cudeb

1. Stock

The result is not bad, but there is some ringing. This might be due to the TL Smoothers or because the shelf, the printer resides on, just isn’t solid enough (wiggles slightly).

First result with stock settings

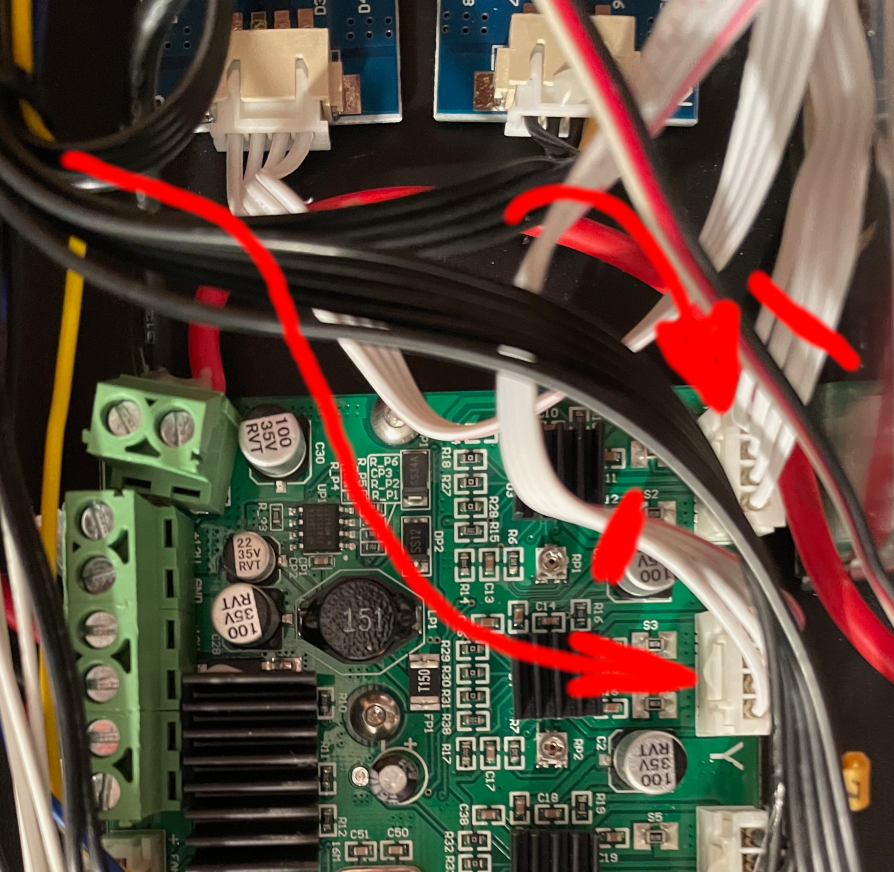

2. No «TL Smoothers»

I have used the same settings and STL file, Just diconnected the smoothers.

Disconnected the TL Smoothers and reconnected the motors directly to stepper drivers

The result looks exactly the same. even the wrinkle right of the upper part of the Y is the same. So no changes but the Smoothers also did not help. So they stay removed.

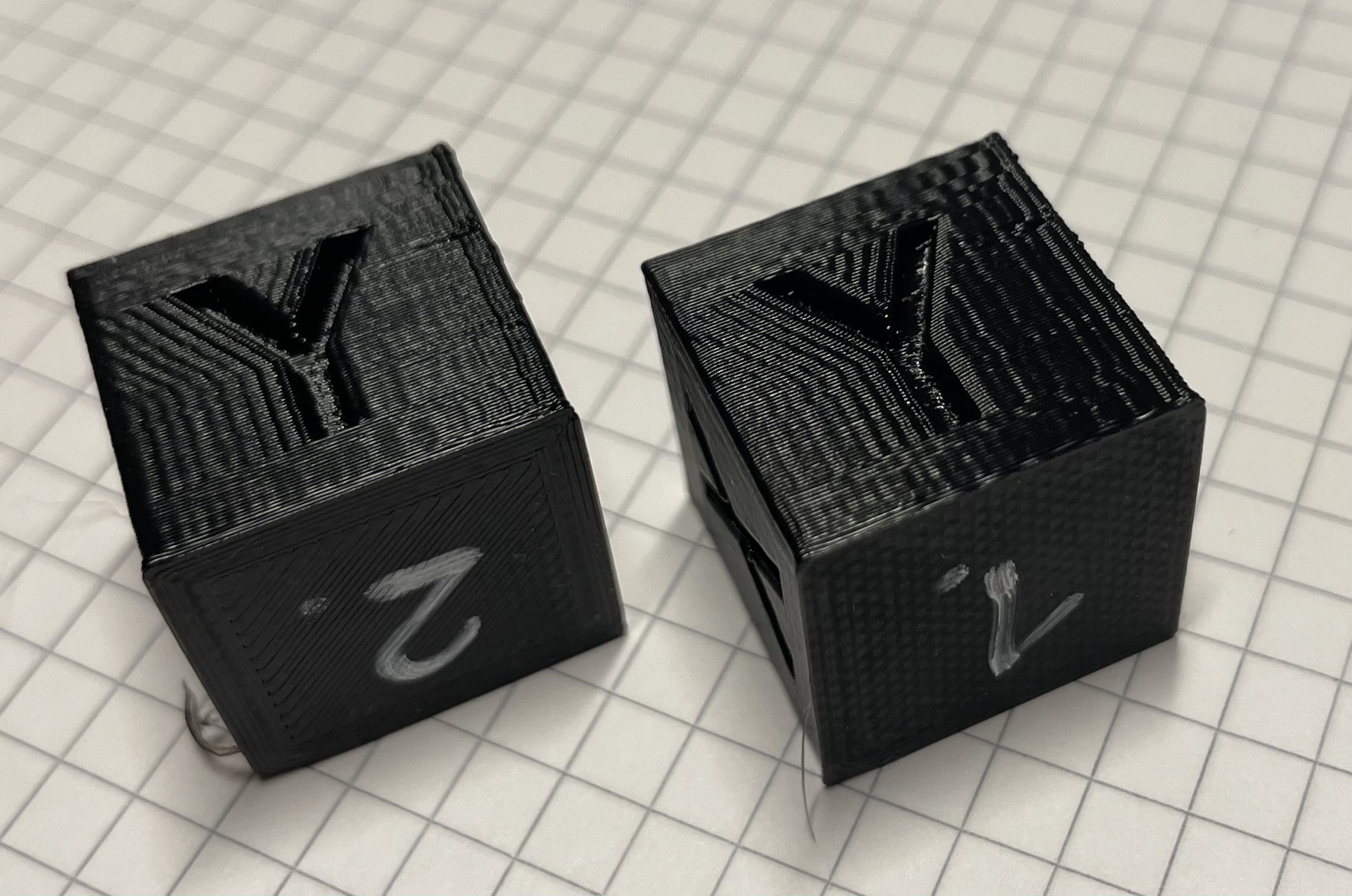

Comparison of print 2 (left) and print 1 (right)

3. floor it

To minimize oscillations from the shelf the printer is placed on, I put the printer on the floor for the next test run. Same settings, same STL and same GCODE as in the last 2 runs.

Comparison of print 2 (left) and print 3 (right)

Not much of a difference, but there is a difference. So we now know that the ringing is partially due to the Movement of the shelf but mostly due to the lack of tuning or the frame flexing.

Analyze Ringing

So the ringing must go. There is a nice test file for Klipper to analyze the ringing frequency. Detailed instructions how to use it can be found in the official Klipper Documentation under Resonance compensation. Long story short, I printed the test G-Code with the follwoing Settings:

Base Extruder Settings

1[general]

2version = 4

3name = PLA Klipper Ender5 -- Standard 0.2

4definition = creality_base

5

6[metadata]

7type = quality_changes

8quality_type = standard

9intent_category = default

10position = 0

11setting_version = 22

12

13[values]

14infill_sparse_density = 0

15material_print_temperature = 185.0

16speed_print = 250.0

Ender 5 Settings (PLA)

1[general]

2version = 4

3name = PLA Klipper Ender5 -- Standard 0.2

4definition = creality_base

5

6[metadata]

7type = quality_changes

8quality_type = standard

9setting_version = 22

10

11[values]

12klipper_accel_limit = 8000

13klipper_accel_to_decel_limit = 1500

14klipper_corner_velocity_limit = 5

15klipper_velocity_limit = 300

16klipper_velocity_limits_enable = True

17material_bed_temperature = 60

Settings

SET_VELOCITY_LIMIT ACCEL_TO_DECEL=7000SET_PRESSURE_ADVANCE ADVANCE=0: pressure_advance: 0.000000 pressure_advance_smooth_time: 0.040000SET_INPUT_SHAPER SHAPER_FREQ_X=0 SHAPER_FREQ_Y=0: Unknown command:“SET_INPUT_SHAPER”TUNING_TOWER COMMAND=SET_VELOCITY_LIMIT PARAMETER=ACCEL START=1500 STEP_DELTA=500 STEP_HEIGHT=5: Starting tuning test (start=1500.000000 step_delta=500.000000 step_height=5.000000)

Now go print the test model sliced with the suggested parameters.

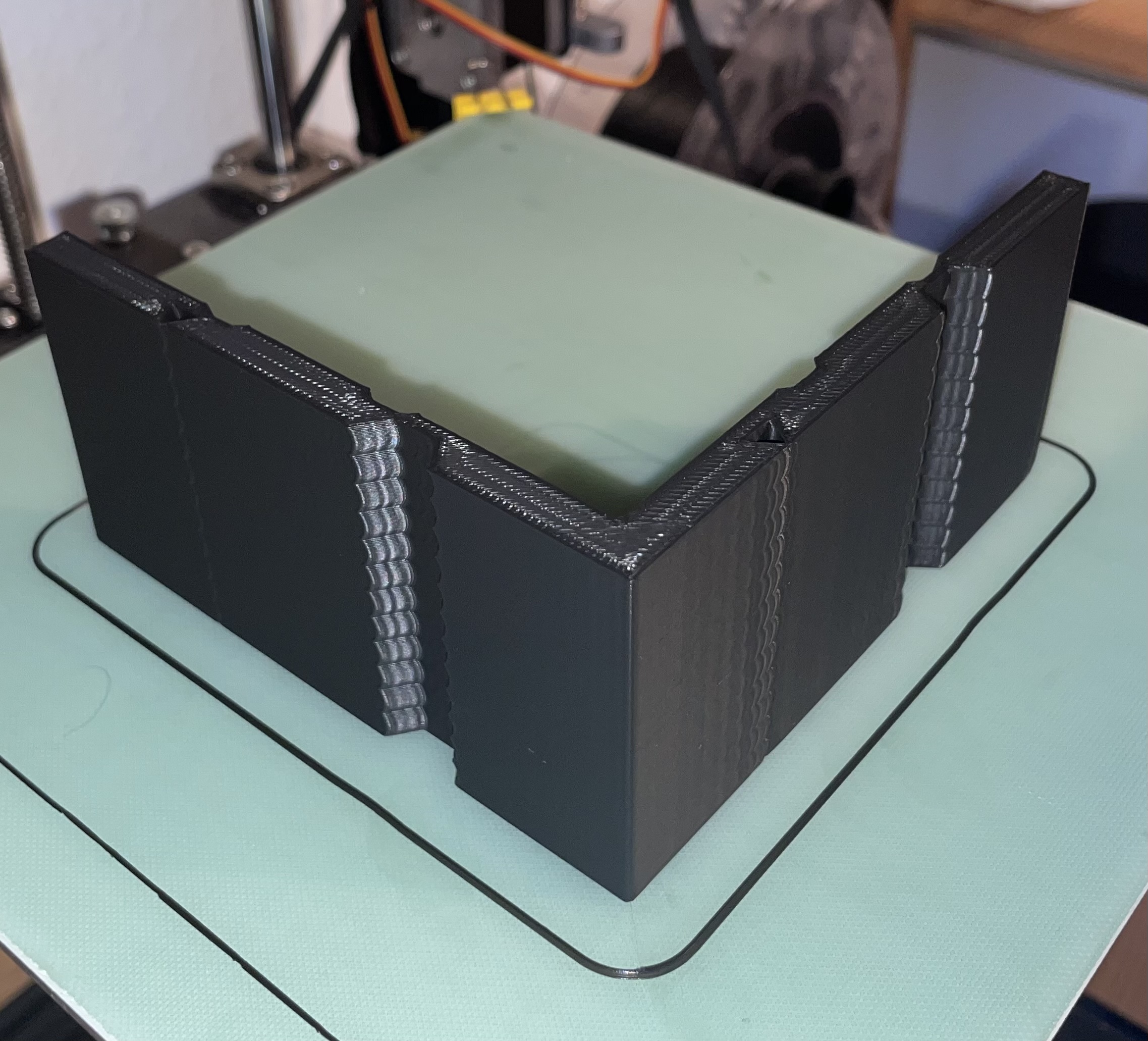

The following G-Code resulted form the above settings: CE5_ringing_tower.gcode and the result looks something like this:

First run of the ringing tower with stock settings.

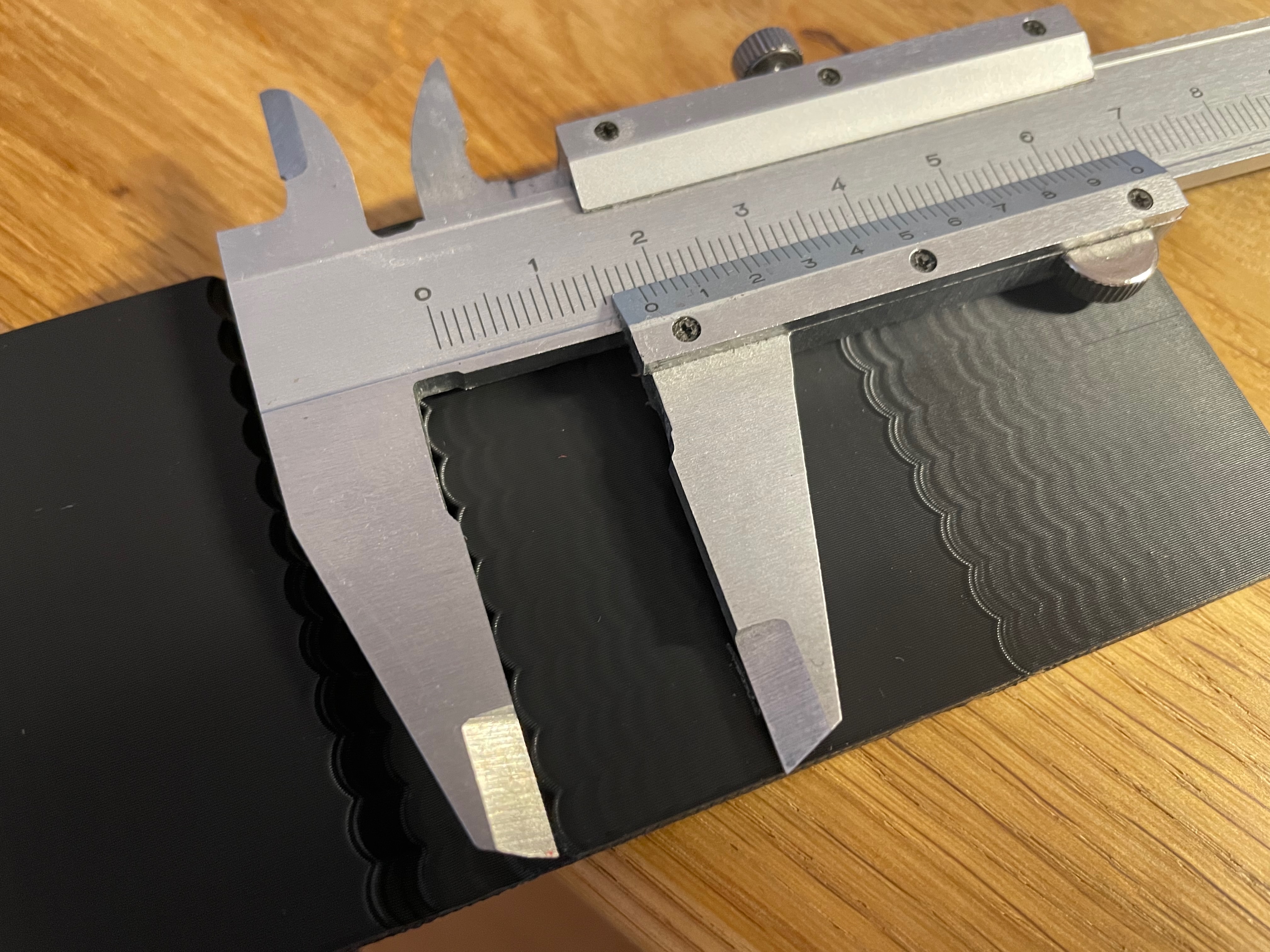

Measure X Axis

Following the instructions in the documentation, these adjustments have been made:

Measuring X-Axis oscillations

8 Osscilations in 18.1 mm

- N: Number of oscillations

- D: Distance measured in mm

- F: Frequency in Hz

Corrections:

- X-Axis:

100 * N / D ≈ F/100 * 8 / 18.1 ≈ 44.19 - Y-Axis:

100 * N / D ≈ F/100 * 8 / 16.4 ≈ 48.78

Save config

Add a section [input_shapre] in printer.cfg.

1[input_shaper]

2shaper_freq_x: 44.19 # frequency for the X mark of the test model

3shaper_freq_y: 48.78 # frequency for the Y mark of the test model

Restart the server to make the change permanent and loaded: SAVE_CONFIG and RESTART.

Verify

Print it again.

Still some miniscule ringing.

Changing shaper config to:

1# Resonance Compensation, must be calibrated per printer

2[input_shaper]

3shaper_freq_x: 44.19 # frequency for the X mark of the test model

4shaper_freq_y: 40 # 2nd: 44, 1st try: 48.78 # frequency for the Y mark of the test model

Retry.

Pressurae Adnvance

SET_VELOCITY_LIMIT SQUARE_CORNER_VELOCITY=1 ACCEL=500TUNING_TOWER COMMAND=SET_PRESSURE_ADVANCE PARAMETER=ADVANCE START=0 FACTOR=.010

The pressure_advance value can then be calculated as pressure_advance = <start> + <measured_height_mm> * <factor>. (For example, 0 + 14.0 * 0.020 would be 0.28).

and print square_tower.stl.

The corners at 14mm look a bit less round then the ones higher up. so I chose this bit to tune the pressure advance.

I could not observe any significant change in corner quality. Also, there is still a fair amount of ringing. Also, the klipper manual really does not explain what should be looked at when examining these pressure towers.

This was a lot of work just to find out, that I do not have to do this when I would be using an accelerometer.

So, it was a nice experiment and I have just ordered an ADXL-345.